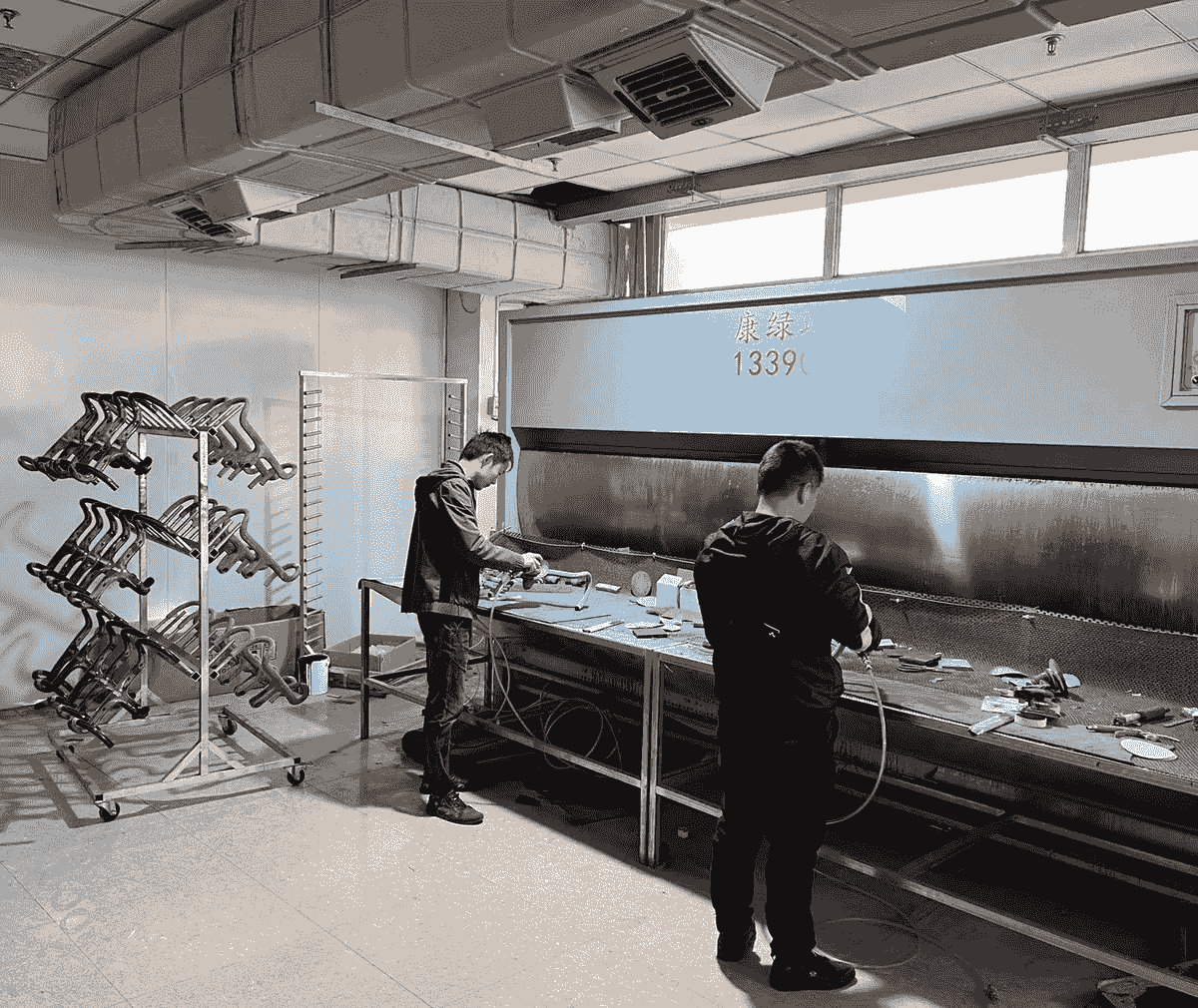

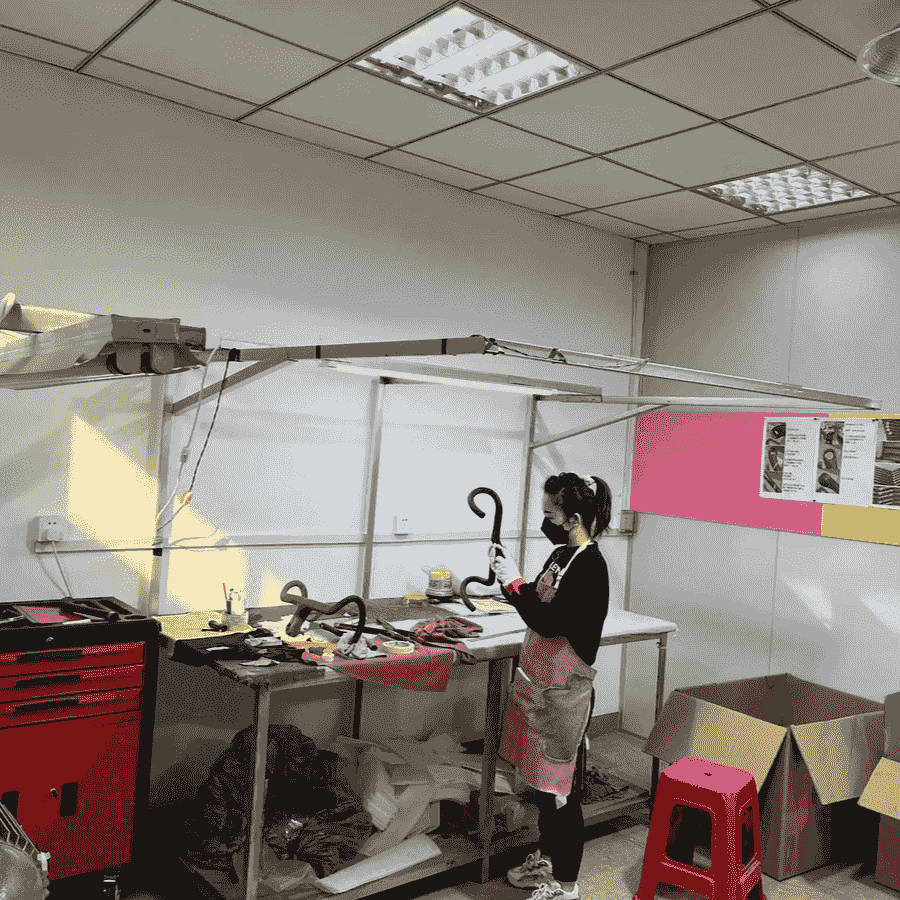

a sneak peek into our workshop

Building on Brand. Integrity First.

Staying True to Our Roots. Consistent Quality.Here’s What We Offer.

Production Team

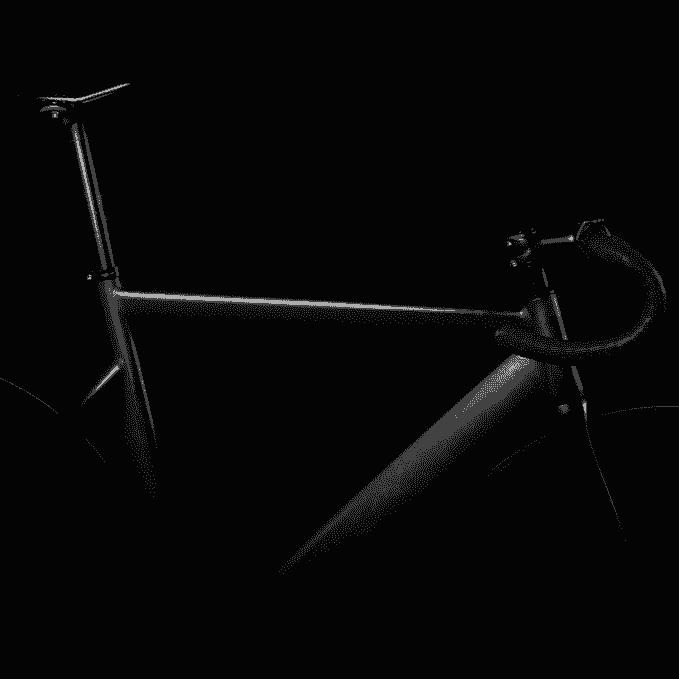

Backed by skilled R&D and production teams, we specialize in high-performance bicycle components crafted from premium materials. Designed to meet the demands of serious riders, our products strike the perfect balance between quality and value—available for both wholesale and retail. We also offer full OEM support and hands-on technical guidance to help our partners bring their vision to life, from first concept to final ride.

We offer a fully integrated production process, covering everything from product design and prototyping to mold development and full-scale manufacturing.

Material Assurance

We stay closely aligned with the latest trends in global cycling technology, ensuring our carbon fiber components deliver the performance today’s riders demand. Engineered for strength, precision, and lightness, our premium carbon fiber accessories are built to keep pace with every challenge the trail—or road—throws your way.

With in-house material science experts, we go beyond conventional methods— we actively explore the possibilities of various material combinations pushing boundaries of what advanced materials can achieve.

Innovative Design & product solutions

Our team is made up of experienced professionals who bring deep expertise from the high-end cycling industry—from hands-on production specialists to technical management leaders. With well-established processes, consistent and stable quality, and access to advanced manufacturing and testing equipment, we ensure every product meets the highest standards—ready for wherever the ride leads.

We provide end-to-end project support, from engineering and design to tooling, testing, and production analysis. During the laminate design process for composite products, we test combinations of various fiber weaving methods matched to real-world stress conditions, ensuring optimal design and presentation of the layup.

Our experienced team specializes in bonding and assembly leveraging multi-component assembly, bonding operations, mechanical fastening, and comprehensive inspection and quality control, delivering fully assembled products that meet the requirements of each project. This product assembly service saves our clients both time and money.

Need molding process solutions? We got it. We offer a variety of options for composite materials molding ensuring your product is realized as quickly as possible.

PREMIUM SERVICE

From production to delivery, we provide full-service tracking on all carbon fiber bicycles and accessories, ensuring you're always supported—no matter the stage. With a well-managed inventory, dependable shipping, and short lead times, we deliver a seamless experience so you can leave the logistics to us and move forward with confidence.

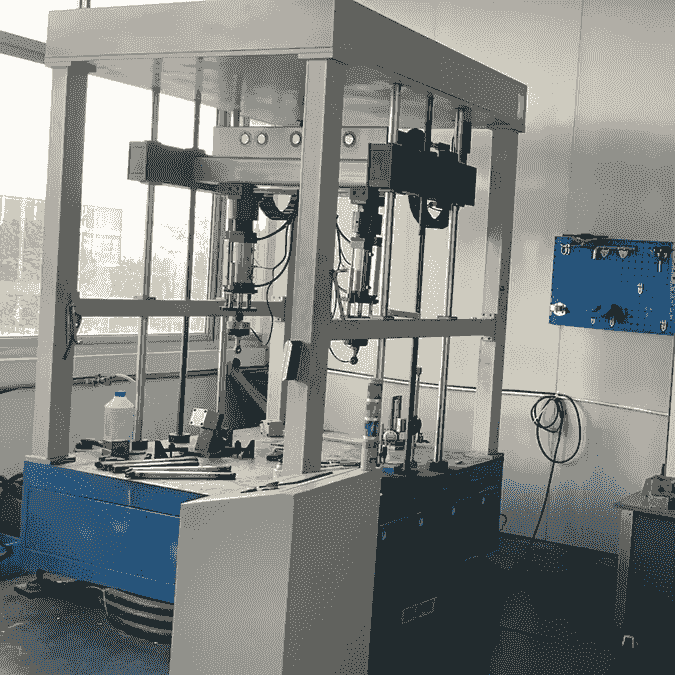

QUALITY ASSURANCE.

full frame fatigue

full frame vibration

full frame impact

rear end impact

sTIFFNESS

front falling

st & ht ultimate

Ht impact

sp fatigue

bb fatigue

disc fatigue

ht fatigue

sp slip test with carbon post

ST Torque test with carbon post

ST Torque Test with mandrel

water bottle bosses torque

we do it best.

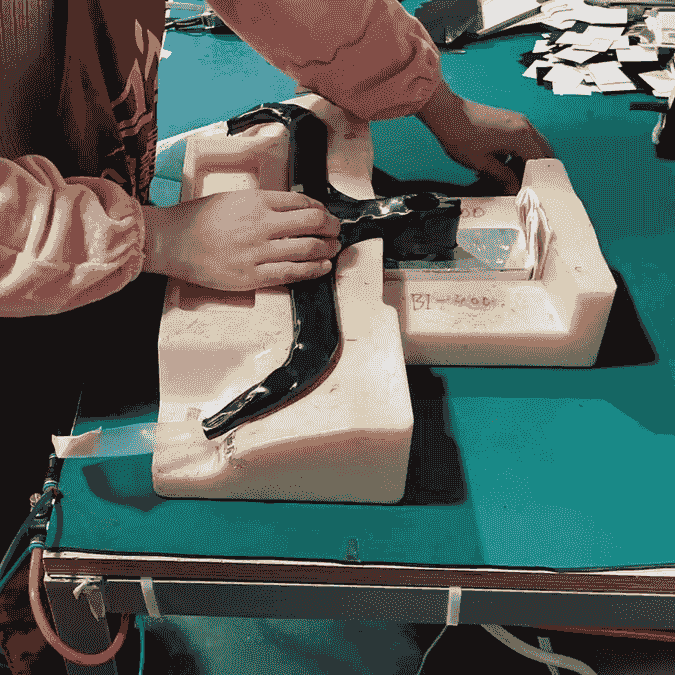

EPS LATEX LAYUP PROCESS

- Silicone, EPS, and Air Cushion Integration Process

- Advanced Latex Manufacturing Process

- PP Blow-Molded Inner Film Technology

advanced molding process

A stable lay-up technique that utilizes custom-shaped fixtures to ensure precise form alignment and improved consistency throughout the lay-up process.

strict testing requirement process

Beyond standard testing, we perform scenario-based simulations that reflect real-world riding conditions—ensuring our products meet practical demands for strength, stiffness, and performance utilizing tools such as:

- Static Testing

- Dynamic Testing

- Kinetic Energy Testing

- Material Testing

- Product Testing

design and engineering process

With years of industry experience, our team brings together expert designers, skilled engineers, and seasoned technicians to deliver precision at every stage of production.

Address

1st Floor, No.32 SiMing Garden, Tongan Industrial District, Xiamen 361100, Fujian province, China

Contact Us

+86 186 1720 5319

+86 187 5927 0367